How to lower a VW Beetle

If an unsightly wheel arch gap is keeping you awake at night, you might be thinking about making a few adjustments. But, before you rush for the nearest socket set there are a few things you should know. Here's our guide on how to lower a VW Beetle.

Get to know VW Beetle suspension

You obviously know by now that Beetles aren’t made like regular cars; they’re much better. But lowering one isn’t simply a matter of bolting on a set of coilovers and winding it down. To lower a Beetle, you’ll have to break out the spanners and make some serious changes to the factory setup. And the lower you go the more radical the work, but everything that bolts on can be removed just as easily, so you can always return a slammed VW to stock, should you be so inclined.

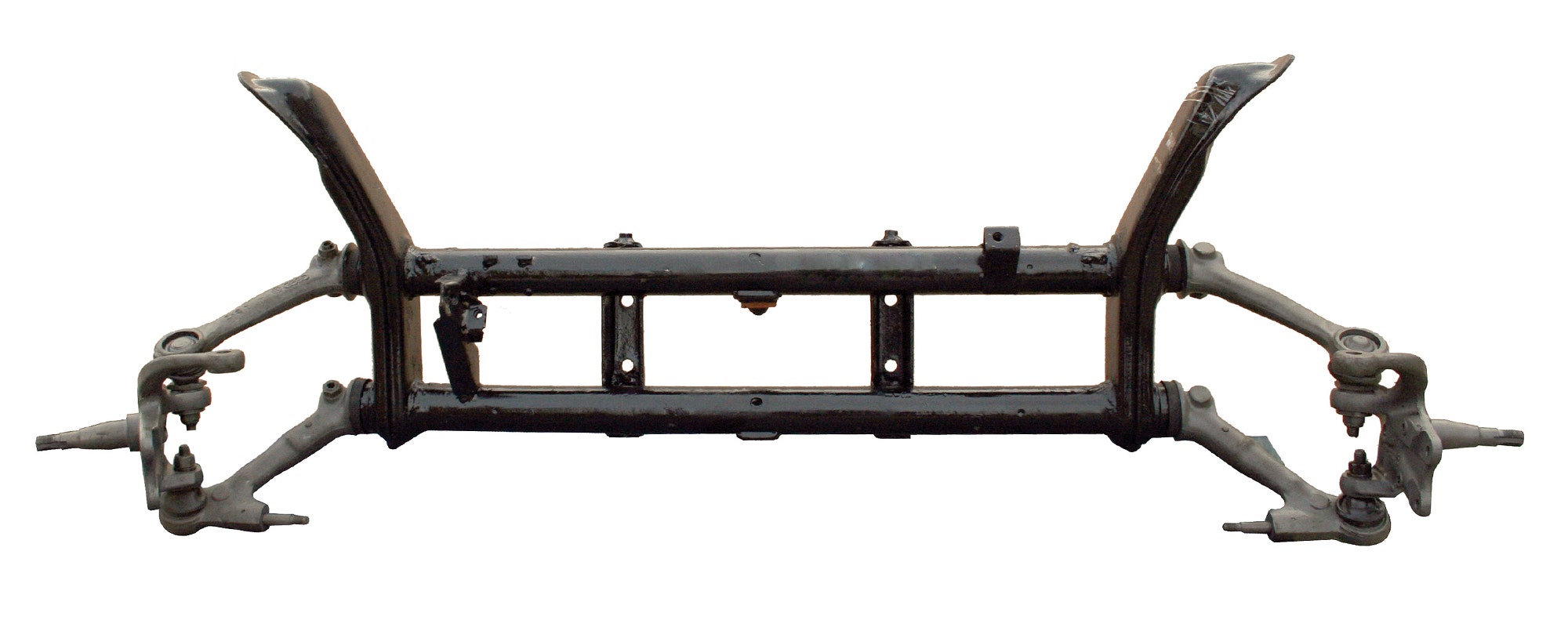

What’s so different about Beetle suspension you ask? Well, take a peep under the front of 'a regular car' and you’ll see either upper and lower wishbones that attach to steering swivel ball joints with a damper mounted in between; or a single lower wishbone with a MacPherson strut that attaches through the bodywork. Both the 1302 and 1303 use this McPherson strut arrangement but they’re the only Beetles that do. Lowering the front of either of those is simply a matter of slotting in a set of Super Beetle lowering springs and fitting shortened shocks if you go beyond a 2" drop. You can’t go as low with 1302 or 1303 as you can with a regular Beetle and neither can you narrow the front end, so if it’s the super-skinny tucked-in look that you favour, these arguably more sophisticated Beetles are not for you. All other Beetles left the factory with torsion bar front suspension. This consists of a bolt-on front beam made up of two horizontal tubes. Each tube contains a set of torsion leaves which are locked in position by a grub screw. Attached to each end is a trailing arm, fixed in place with a grub screw and lock nut. When the trailing arms go up and down the leaf pack tries to twist but the central grub screw fights this torsional rotation and returns the leaf pack to its original position. These two torsion bars provide the suspension but they also determine the vehicle’s ride height. It's worth noting that the Karmann Ghia also shares the same suspension setup as the Beetle, and whilst not identical, the VW Type 3 follows a similar principle.

Ball Joint or King and Linkpin Beam?

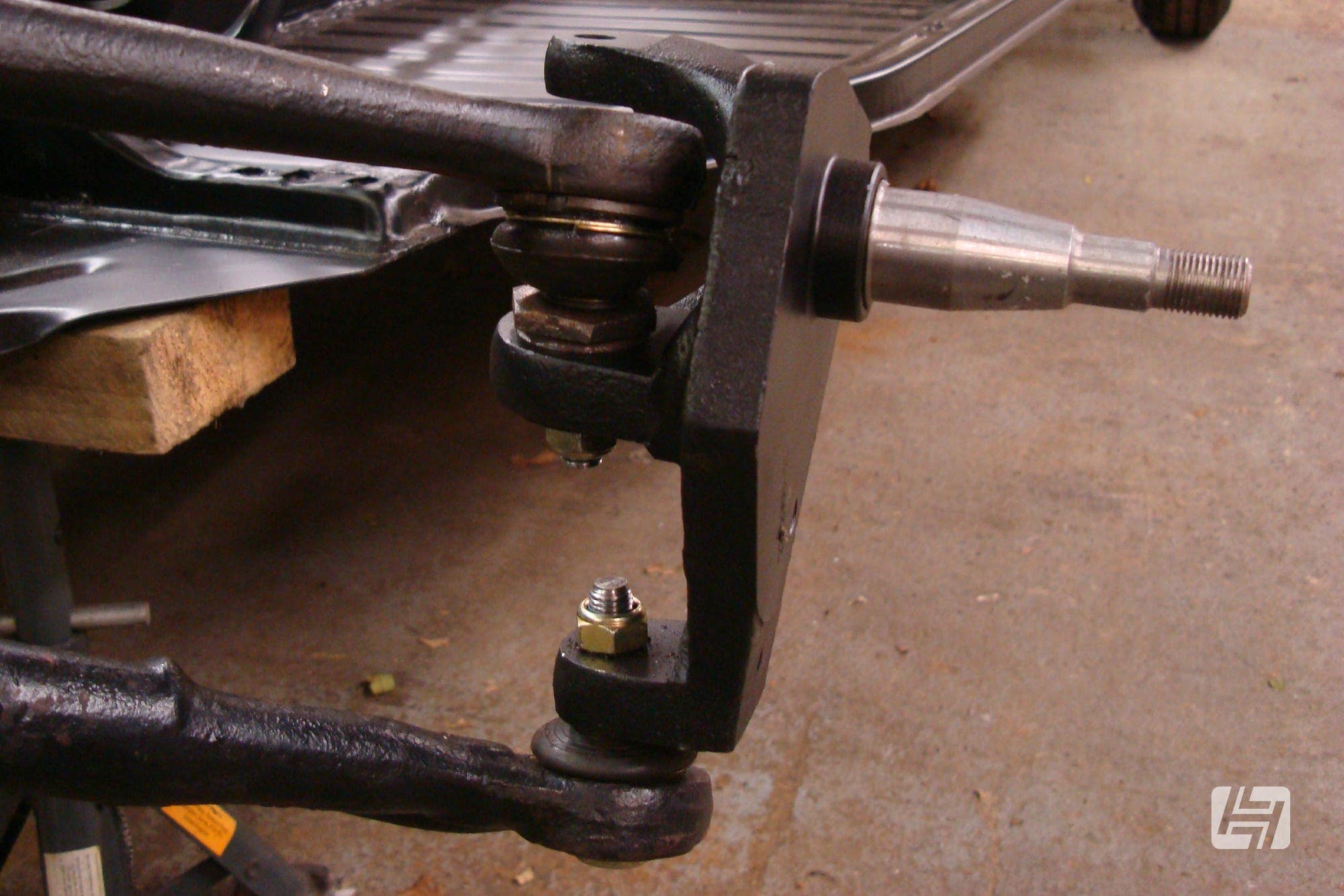

VW Beetle beams come in two varieties and it’s entirely dependent on the year your car was built. All Beetles produced prior to August 1965 run what are known as 'link pin' beams and after that, they have 'ball joint' beams. A king and link pin front axle has spindles that rotate on a large vertical kingpin and the pin is held onto the torsion arms with two horizontal link pins. You can buy a replacement link pin kit here, but fitting them is something best left to a professional as you need a press to install them. VW switched to ball joints for the 1966 model year because they thought they’d require less maintenance. However, the rubbers perish, dirt creeps inside and damages the joint; getting the nut off the ball joint can be a pain if the ball joint spins in the torsion arm too. Ball joint spindles mount directly onto the threaded bolts of the two ball joints. Long travel ball joints are a common addition on lowered cars.

Which beam is best if you want to go low?!

Some people will argue a later Beetle with a ball joint beam has a smoother ride in standard trim, but there’s no denying this soon changes when it is lowered. The link pin beam is the preferred choice for enthusiasts looking to go low. From a ground clearance point of view, the link pin axle is also smaller in height, measuring 7 inches, an inch less than the ball joint version, and that is really important if a hard slam is on the cards. It is possible to replace a ball joint beam with a link pin one, but you’re looking at an awful lot of work cutting out and replacing the frame head to do so. If you're serious about scraping the sills, then this modification could be carried out whilst raising the frame head, lifting the front beam mounting points further up. Unless you are a competent welder, this job is best left to a skilled workshop. Also bear in mind, the fuel tank will need raising for clearance at the front and you might then choose to lift the engine and gearbox to match at the back! It's a slippery slope...

What is an adjustable beam?

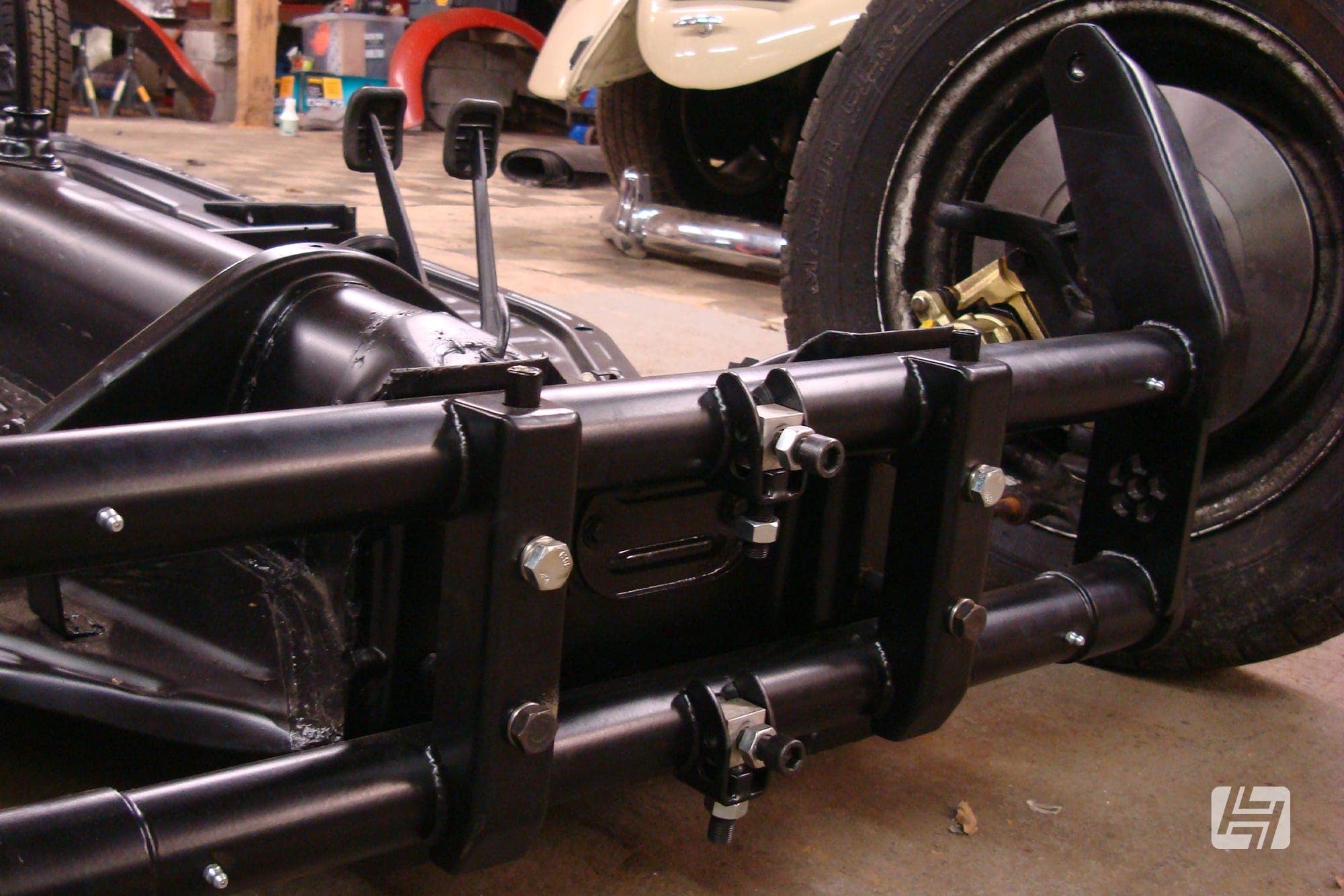

Now you know how the beam axle works, let’s talk about modifying it. Back in the old days, everyone was happy just knocking an inch or three out of their ride height. The budget solution was to cut out the central grub screw and reposition it further around the beam, thus relocating the fixing point in a lower (or higher) position. The problem with this is you needed to know where to set it and once you’d welded it in position there was no way of adjusting it. The solution to that was to cut out the centre of the beam entirely, and weld in a beam adjuster. The adjuster is basically an elongated hole that gives the grub screw space to move up and down. You slacken off the lock nut and wind the adjuster bolt in or out to raise/lower the front end. When you’re happy with the ride height you wind the lock nut in and fix the torsion bars in their new position. Simple but effective.

What is a narrowed beam?

These days, the majority of lowered Beetles run a narrowed beam. It’s predominantly a fashion thing that you either love or loathe but there is also a very practical reason behind them. You can only go so low with a stock-width beam, and to many that just isn’t considered low enough. Drop the front end of a Beetle by more than a couple of inches and you’re likely to run into clearance issues. The wheels and tyres will rub on the front wheel arches and the likelihood of this increases when you install other items, such as VW Beetle alloy wheels, wider tyres, disc brake conversion and dropped spindles, which we’ll circle back to in a moment. If you only want to tuck the front wheels back in after fitting discs or spindles, then a two-inch narrowed beam will do the trick. It won’t affect the car's turning circle and you can still run a front anti-roll bar. If two inches isn’t enough, then a four-inch or six-inch chop is possible. This involves removing the width from the central axle tubes and is supported by making the shock towers thinner too. The amount you narrow the beam will also determine how much has to be removed from the torsion bar leaves. These need to be cut down by the same amount as the beam and will need new dimples drilled in them for the repositioned grub screws. You'll also need to shorten the tie rods and steering arms, but many of these are available to buy new, rather than making them yourself.

What other VW Beetle Suspension parts will I need?

Everything you fit will have a knock-on effect on what comes next. For example, how low do you want your car? What size wheels and tyres are you going to be running? Are you going to convert the brakes to discs? All of these factors come into play when you drop the front end of a Bug. Will you need shorter shocks and which ones should you choose? What style are you going for? Is the car going to sit level or do you want to have a nose-down Cal Look rake? If so, you’ll need to install some caster shims behind the top tube to correct the steering geometry. How narrow do you want the front end to be? Two and four-inch beams are the most common, but some people go for a six-inch beam, eight, or even more. Get into that territory and you’re going to run into issues with the shock towers, Beetle inner wings, and headlight bowls. If you see a car with a really skinny front end the chances are it’s running a shock-less beam. This would be frowned upon by your MoT tester (assuming you still put your car through an annual check) and possibly your insurance company in the event of an accident, so you need to go into such drastic modifications armed with all the facts. If it is parked with the running boards on the floor then it's almost certainly running air-ride or hydraulics - we'll cover that subject another day.

What are Dropped Spindles?

These are something you’ll often hear mentioned in the same breath as any beam modification. The spindle is the component the front brake drum or disc attaches to. Many years ago, some bright spark came up with the idea of raising the spindle by a couple of inches. This raises the wheel further up in the front arch and therefore drops the front of the car down by the same amount. Dropped spindles are ideal for someone looking for a mild drop without any further modifications and have no adverse effect on handling. If anything, they tighten the feel of a front end up and reduce the amount of body roll. They will also give you 2.5-inches of free drop before you start messing with anything else, if you want to go really low. VW Beetle dropped spindles are available for both drum and disc-equipped cars and link pin and ball joint front beams, and usually lower a car by around 2.5-inches. Because of their design, they will increase the track width by approximately half-inch per side, so allow for that with any axle and wheel calculations you might make.

How to lower Beetle rear suspension

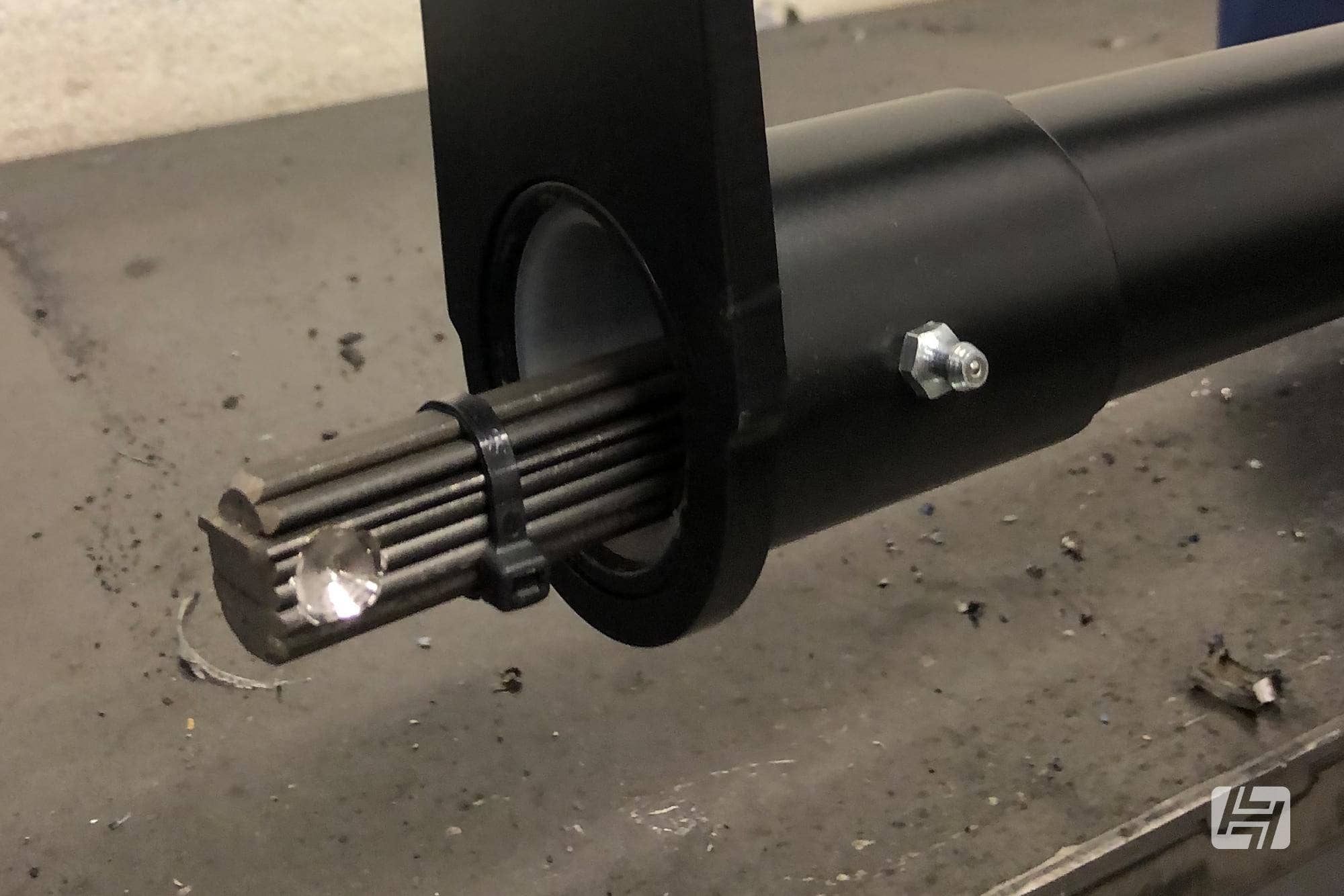

The rear end, like the front, has torsion bar suspension but is actually much less involved to adjust. The rear spring plates locate on the splined torsion bar ends and by removing them and repositioning them on the splines, you can raise or lower the rear ride height accordingly. What scares a lot of people is the number of splines there are on the bar ends. There are 40 on the inner end and 44 on the outer. You can change the ride height by reindexing the inner or outer or both sets of splines and this is what confuses most. If you’ve never worked on a Beetle rear end we’d suggest enlisting the help of a friend who has, and mark both the torsion bar and spring plates so you have a reference point should you need to go back and start again. The good and bad news is that Beetle rear ends tend to lower themselves over time anyway. They sag on the spring plates so you may not need to play with them at all. The bad part of this is they don’t sag evenly side to side, which can make getting a car to sit level a real nuisance. The best way to lower and fine-tune the rear end of a Beetle is to fit adjustable spring plates. They have an adjuster bolt that can be wound up or down to really dial in the height.

Do I need to cut the body to lower my Beetle?

Unless you go down the route of raising the front end or the engine and gearbox, you shouldn’t need to do a great deal in this area. On the body, you may need to weld some shock absorber mounts on the inner wings, if you’re running a shockless beam. The headlight buckets can foul on the front tyres if they’re too big. You can fit lower profile tyres which will reduce the rolling radius, making the overall wheel and tyre small. You can also 'dress' the headlamp buckets with a hammer until you have the clearance you need. The more sophisticated and expensive fix is to buy some extended trailing arms that reposition the wheel in the centre of the arch. Set the back end down and you might find the jacking points catch on the floor. The solution is to simply cut them off the floor pan. If your car is really low you can weld in flat pan sections to raise the rear of the floor pan a little.

Pros and Cons of lowering your VW Beetle

The big pro is a lowered VW Beetle looks cool. If you disagreed with that you wouldn’t have read all the way down to here. Everything you need is available to buy off the shelf and there’s nothing that hasn’t been done before, so there’s plenty of helpful advice to be had. The cons need to be considered, but most people ignore them anyway and just put up with things like a reduced turning circle, a car that bumps and scrapes if it’s too low, and just the impracticality of having a car with reduced ride height. If practicality is a deal-breaker, then air-ride or hydraulic suspension would allow you to lift and drop at the flick of a switch, but it won't come cheap. Even with a static drop, there is a time commitment and expense to lower a Beetle, and be wary that Beetle suspension components will wear out faster running that low. It's also worth noting, that your insurance premium may well go up, so check that before the tools come out. It’s your call...

Best of luck

James / Andy

Beetle

Beetle

T2 Bay

T2 Bay

T2 Split

T2 Split

T25

T25

Transporter T4

Transporter T4

Transporter T5

Transporter T5

Golf Mk1

Golf Mk1

Golf Mk2

Golf Mk2

911

911

996

996

997

997

986 Boxster

986 Boxster

987 Boxster

987 Boxster

912

912

944

944

924

924

Defender

Defender

Discovery Series 1

Discovery Series 1

Discovery 2

Discovery 2

Series 1, 2 & 3

Series 1, 2 & 3

Freelander

Freelander

Freelander 2

Freelander 2